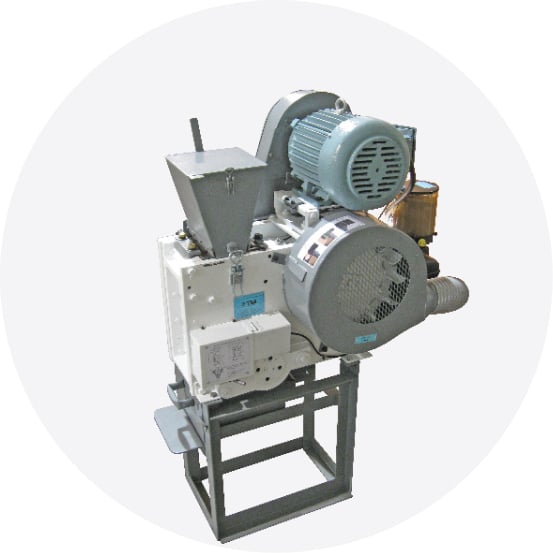

Terminator Jaw Crusher

SUPERIOR CRUSHING, UNCOMPROMISED RELIABILITY, BUILT FOR POWER, DESIGNED FOR PRECISION

The Terminator Jaw Crusher is the ultimate in fine crushing. Unmatched for its crushing speed, consistent material reduction and reliability! With actual material fineness of 95% minus 2mm after a single 110 feed pass, the Terminator is designed to last and incorporates unique features setting it apart from its competitors.

In laboratories, it’s used for sample preparation, where it can crush geological samples into smaller sizes for further analysis. The small particle size output is ideal for various analytical processes.

In mining and construction, it is employed to break down large rocks, gravel, or chunks of concrete into smaller, manageable pieces. This is vital for the processing of materials, whether it’s for subsequent stages of processing or for removal.

The Terminator Jaw Crusher’s unique cooling system, narrow profile, automatic lubrication, and easy single-side adjustment of output size allow it to perform under the harshest conditions and in tight operating spaces, including mobile container laboratories. Its reliability, ease of maintenance, and the availability of different crushing jaws make it a go-to choice across multiple industries. Its optional accessories also help in controlling dust emissions and ensuring safety, which are essential in the industrial working environment.

STANDARD FEATURES

Equipped with an automatic greasing system, ensuring consistent and repeated lubrication for high performance under heavy operations.

Comes with smooth or serrated, reversible and interchangeable crushing jaws. Jaws can be easily removed via a simple clamping mechanism.

Features single-point jaw adjustment, providing easy control to meet required feed output size. • Includes a ducted fan cooling system, maintaining optimum temperature for the unique eccentric bearing, even in extremely hot climates.

Its narrow profile makes it perfectly suited for operations in tight spaces, such as mobile container laboratories.

OPTIONAL ACCESSORIES

Optional machine-mounted Stop/Start/E-Stop Controller for enhanced operation control.

Environmental enclosure, including a stand with drawer, for improved protection and storage.

Dust collecting hopper, aiding in maintaining a clean work environment.

Safety hopper, available in short or tall sizes, providing additional safety during operation.

Optional accessories for vibration control.